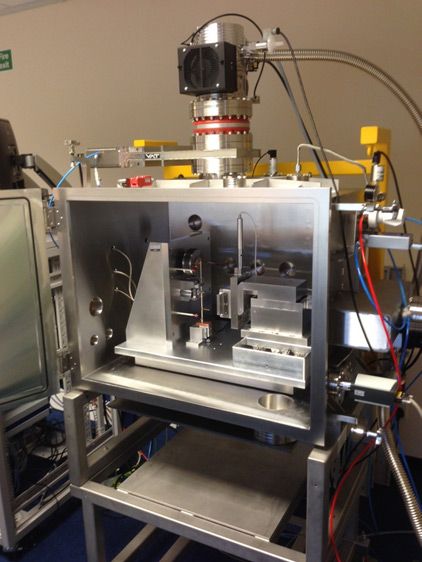

NANOTEST XTREME

PRODUCER: MICRO MATERIALS

Researchers are increasingly demanding that test conditions closely mimic real-world environments in order to provide the most reliable, accurate prediction of properties. With the NanoTest Vantage, Micro Materials already offers the most comprehensive range of nano-mechanical test options. These are now further extended with the NanoTest Xtreme, which provides a vacuum environment testing from -100 to 1000 ºC without oxidation or frosting of samples.

Check out our new testing at 1000 ºC application note which includes real-world examples from some of our NanoTest Xtreme users.

REQUEST OFFERSuitable for investigating the effect of more extreme environments than ever before for:

- Low oxygen, low temperatures for satellite development

- High temperatures for aerospace engine components

- High temperatures for power station steam pipes

- Irradiation effects in nuclear reactor cladding

- The effect of cold on weld repairs in oil/gas pipelines

- Tool coatings for high speed machining

Test temperatures from -100 to 1000 ºC

Micro Materials has considerable experience in providing instruments capable of high and low temperature testing. Until recently, the limitations of these have been oxidation at high temperatures and condensation/frosting at sub-zero temperatures. Testing under vacuum negates these and allows further expansion of the temperature capabilities of the NanoTest.

The benefits to users are:

- Extended high temperature capabilities beyond the 850 °C provided by the NanoTest Vantage

- Enhanced low temperature capability to below -100 °C without frosting of samples

- Ultra-low thermal drift due to same construction principles as those used on the proven NanoTest Vantage

- Complete range of nano-mechanical tests remain available, including indentation, scratch, wear, friction and high-load impact

- Ability to backfill with gas to match material operating environments